OSHA 10

Before the establishment of the Occupational Safety and Health Administration (OSHA) in 1970, workplace safety regulations were minimal, leading to hazardous conditions for many workers. The lack of standardized safety measures resulted in high rates of workplace injuries and fatalities.

Module 1 - Intro to osha

OSHA Act of 1970 and Workers' Rights

The Occupational Safety and Health Act (OSHA) of 1970

The OSHA Act was established to ensure safe and healthy working conditions for employees by setting and enforcing standards and by providing training, outreach, education, and assistance. It created the Occupational Safety and Health Administration (OSHA) under the Department of Labor.

Study Guide

OSHA Module 1 Quiz: Introduction to OSHA

1. What year was the Occupational Safety and Health Administration (OSHA) established?

a) 1965

b) 1970

c) 1985

d) 1990

2. Which U.S. Department is responsible for OSHA?

a) Department of Health and Human Services

b) Department of Labor

c) Department of Transportation

d) Department of Justice

3. What is the main purpose of OSHA?

a) To regulate the pay scale for workers

b) To enforce labor union laws

c) To ensure safe and healthy working conditions for employees

d) To control the number of workers in hazardous jobs

4. Under the OSHA Act, what are employers required to provide for their employees?

a) Free meals and drinks

b) Safe and healthful working conditions

c) Personal transportation

d) Paid vacation time

5. What is the OSHA General Duty Clause?

a) Employers must provide paid sick leave

b) Employers must provide safe and healthy working conditions

c) Employers must train employees in every safety standard

d) Employers must ensure that workers get a set number of breaks

6. Which of the following is an example of a worker's right under OSHA?

a) The right to refuse work if it’s unsafe

b) The right to choose their own working hours

c) The right to paid overtime

d) The right to avoid company meetings

7. Which of the following is NOT the responsibility of employers under OSHA?

a) Provide training on workplace hazards

b) Provide the necessary personal protective equipment (PPE)

c) Report employee misconduct to OSHA

d) Ensure that work environments are free from recognized hazards

8. Which of the following can workers do without fear of retaliation?

a) Complain about unfair pay

b) Complain about unsafe working conditions

c) Refuse to work for any reason

d) Take a sick day without notice

9. How can employees file a complaint with OSHA if they feel their workplace is unsafe?

a) Only through a union representative

b) By filing a written complaint through the OSHA website, by mail, or by phone

c) By directly approaching their supervisor

d) Only through their company's internal safety committee

10. What happens if OSHA finds that an employer is violating safety standards?

a) The employer is given an extension to fix the problem

b) The employer is not informed until the issue causes an accident

c) The employer is required to pay a fine and correct the violation

d) The employer is immediately shut down

Module 4 - Struck-By Hazards and How to Avoid Them

Struck-by Hazards

Struck-By Hazards

Struck-by hazards occur when a worker is hit by an object or vehicle, causing injuries or fatalities. According to OSHA, struck-by hazards are one of the Fatal Four causes of workplace fatalities in construction, contributing significantly to deaths and injuries.

Study Guide

Struck-By Hazards Quiz

1. Which of the following is NOT a common cause of struck-by hazards?

a) Moving vehicles

b) Falling objects

c) Loud noises

d) Flying debris

2. What is the best way to prevent being struck by moving equipment on a construction site?

a) Wearing a reflective vest and staying in designated walkways

b) Walking behind heavy machinery at all times

c) Ignoring backup alarms since they are repetitive

d) Relying on drivers to always see pedestrians

3. What type of struck-by hazard occurs when materials are ejected from tools such as saws or nail guns?

a) Struck-by falling object

b) Struck-by flying object

c) Struck-by rolling object

d) Struck-by swinging object

4. What should workers do to prevent being struck by falling objects?

a) Wear hard hats at all times

b) Stack materials securely and use toe boards

c) Avoid standing under suspended loads

d) All of the above

5. Why is it dangerous to position yourself between a fixed object and moving equipment?

a) It can cause minor inconvenience to the equipment operator

b) You could be caught in a pinch point and severely injured

c) It makes it easier to guide the equipment

d) It is actually a recommended safety practice

6. How can workers reduce struck-by hazards when using power tools like nail guns?

a) Always aim the tool away from themselves and others

b) Ensure proper training and maintenance of tools

c) Wear eye and face protection

d) All of the above

7. What does OSHA require for workers near traffic zones on a job site?

a) High-visibility vests or clothing

b) No PPE is needed for traffic areas

c) They must wear only ear protection

d) Workers should walk in the middle of the roadway

8. What type of PPE is most commonly used to protect against struck-by hazards?

a) Earplugs

b) Steel-toe boots, safety glasses, and hard hats

c) Dust masks

d) Knee pads

9. What is the purpose of a spotter when working around heavy equipment?

a) To operate the machinery when the driver is unavailable

b) To direct and communicate with equipment operators to avoid collisions

c) To monitor weather conditions

d) To ensure materials are stacked properly

10. How can workers stay safe when working around overhead loads?

a) Avoid walking under suspended loads

b) Ensure loads are properly rigged and secured

c) Use barricades and warning signs to keep workers out of danger zones

d) All of the above

Module 8 - ladder and scaffold safety

Ladder and Scaffold Safety

Falls from ladders and scaffolds are a leading cause of injury and fatalities in construction. Understanding the proper use, inspection, and maintenance of these tools is essential for workplace safety.

study guide

OSHA Module 8: Ladder and Scaffold Safety Quiz

1. What is the minimum extension a ladder must have above a landing surface?

A) 1 foot

B) 2 feet

C) 3 feet

D) 4 feet

2. Which of the following is NOT a type of scaffold?

A) Suspended Scaffold

B) Supported Scaffold

C) Rolling Scaffold

D) Hinged Scaffold

3. What is the required safety factor for the load capacity of a scaffold?

A) 2 times the intended load

B) 4 times the intended load

C) 6 times the intended load

D) 8 times the intended load

4. When using a ladder, how many points of contact should a worker maintain?

A) 1

B) 2

C) 3

D) 4

5. How often should ladders and scaffolds be inspected?

A) Once a month

B) Once a year

C) Before each use

D) Only when issues arise

6. What must be installed on scaffolds higher than 10 feet to prevent falls?

A) Guardrails

B) Netting

C) Personal Fall Arrest Systems

D) All of the above

7. What is a common defect that should result in a ladder being removed from service?

A) A single scratch on the paint

B) A missing or broken rung

C) Light surface rust

D) Dirty steps

8. What is the primary purpose of toe boards on scaffolds?

A) Provide foot support for workers

B) Prevent tools and materials from falling

C) Make climbing easier

D) Reinforce the scaffold structure

9. Which OSHA regulation covers ladder safety?

A) 29 CFR 1926.1053

B) 29 CFR 1910.23

C) 29 CFR 1926.451

D) All of the above

10. What is the correct way to store a ladder?

A) Laying flat on the ground

B) Propped up vertically without support

C) In a dry, stable location to prevent warping

D) Leaned against a wall for easy access

Hazard Communications

module 2 - Fall Protection

Fall Hazards and Fall Protection Systems

Introduction to Fall Hazards

Falls are one of the leading causes of serious injuries and fatalities in construction. OSHA's fall protection standards aim to prevent falls by requiring employers to provide safe working conditions and fall prevention systems.

Study Guide

OSHA Module 2: Fall Hazards Quiz

At what height does OSHA require fall protection in the construction industry?

a) 4 feet

b) 6 feet

c) 10 feet

d) 15 feetWhich of the following is NOT a common fall hazard?

a) Unprotected edges

b) Properly secured scaffolds

c) Improper ladder use

d) Unstable walking surfacesWhat is the minimum weight capacity an anchorage point must support for a personal fall arrest system (PFAS)?

a) 2,500 lbs

b) 3,000 lbs

c) 5,000 lbs

d) 10,000 lbsWhich of the following is a passive fall protection system?

a) Safety harness

b) Lanyard

c) Guardrails

d) Self-retracting lifelineHow far below the work surface must safety nets be installed?

a) 10 feet

b) 20 feet

c) 25 feet

d) 30 feetWhich of the following is a requirement for guardrails?

a) Must be at least 42 inches high

b) Must withstand 100 lbs of force

c) Must be placed every 10 feet

d) Must include toe boards only when requestedWhat is the most common cause of falls from ladders?

a) Using a ladder made of aluminum

b) Overreaching or improper use

c) Wearing non-slip shoes

d) Using a harness while on the ladderOSHA requires that scaffolding be fully planked. What is the purpose of this requirement?

a) To allow for more storage space

b) To prevent workers from stepping into gaps and falling

c) To make scaffolding easier to disassemble

d) To increase ventilation on the job siteWhich of the following must be done when working on a roof near unprotected edges?

a) Wear a hard hat

b) Use a personal fall arrest system or guardrails

c) Walk only on designated paths

d) Only work during daylight hoursWhat is the best way to ensure workers properly use fall protection equipment?

a) Conduct regular safety training and inspections

b) Provide fall protection gear but leave usage up to the worker

c) Only require fall protection for workers new to the job

d) Allow workers to decide if they feel comfortable using fall protection

Module 5: Caught-In/Between Hazards

Caught-In/Between Hazards

Caught-in/between hazards are among the Fatal Four leading causes of construction worker fatalities. These hazards occur when a worker is trapped, crushed, or squeezed between objects, equipment, or structures. This module will help workers recognize, prevent, and mitigate caught-in/between hazards with a focus on trenching and excavation hazards, machinery and equipment safety, and confined spaces.

Study Guide

Caught-In/Between Hazards Quiz

1. What is a caught-in/between hazard?

a) A hazard where a worker is trapped or crushed by equipment, materials, or structures

b) A hazard involving exposure to harmful chemicals

c) A hazard caused by falling from heights

d) A hazard caused by high noise levels

2. Which of the following is a major cause of trench collapses?

a) Improper use of safety equipment

b) Lack of protective systems (sloping, shoring, or shielding)

c) Poor lighting in the trench

d) Inadequate ventilation

3. What is required by OSHA when a trench is 5 feet or deeper?

a) Proper signage only

b) Protective systems like shoring, sloping, or shielding

c) A worker must wear a safety harness

d) The trench must be covered at all times

4. Which of the following is an appropriate safety measure when using heavy machinery on a construction site?

a) Never use spotters to guide equipment

b) Ensure all moving parts are unguarded to prevent damage

c) Workers should wear high-visibility PPE and stay clear of moving equipment

d) Operators should work without breaks to maintain productivity

5. How can workers protect themselves from being caught between machinery and structures?

a) By standing near the equipment to monitor its operation

b) By maintaining a safe distance from machinery and using proper signaling

c) By avoiding the use of machines altogether

d) By staying in the same position and not moving

6. What is the main purpose of Lockout/Tagout (LOTO) procedures?

a) To prevent unauthorized personnel from accessing equipment

b) To ensure machinery is shut off and energy sources are isolated during maintenance

c) To speed up equipment repairs

d) To increase the efficiency of machinery

7. In a confined space, which of the following is required before entry?

a) Only the supervisor must enter

b) Ventilation and atmospheric testing must be conducted

c) Workers must work in teams of at least 10

d) No special requirements are needed for confined space entry

8. What should be done before workers enter an excavation site?

a) Ensure all equipment is operational

b) Confirm there is no heavy machinery operating nearby

c) Inspect for potential cave-ins and use proper protective systems

d) Workers should enter without any preparation to meet the deadline

9. What does OSHA require regarding access and egress for trenches 4 feet or deeper?

a) Access and egress points are not necessary for trenches under 10 feet

b) A ladder, ramp, or other safe means of exit must be provided within 25 feet of workers

c) Workers can climb out of the trench at any point

d) Access and egress are only needed in emergency situations

10. What is the minimum distance machinery should be kept from the edge of an excavation or trench?

a) 3 feet

b) 5 feet

c) 10 feet

d) 2 feet

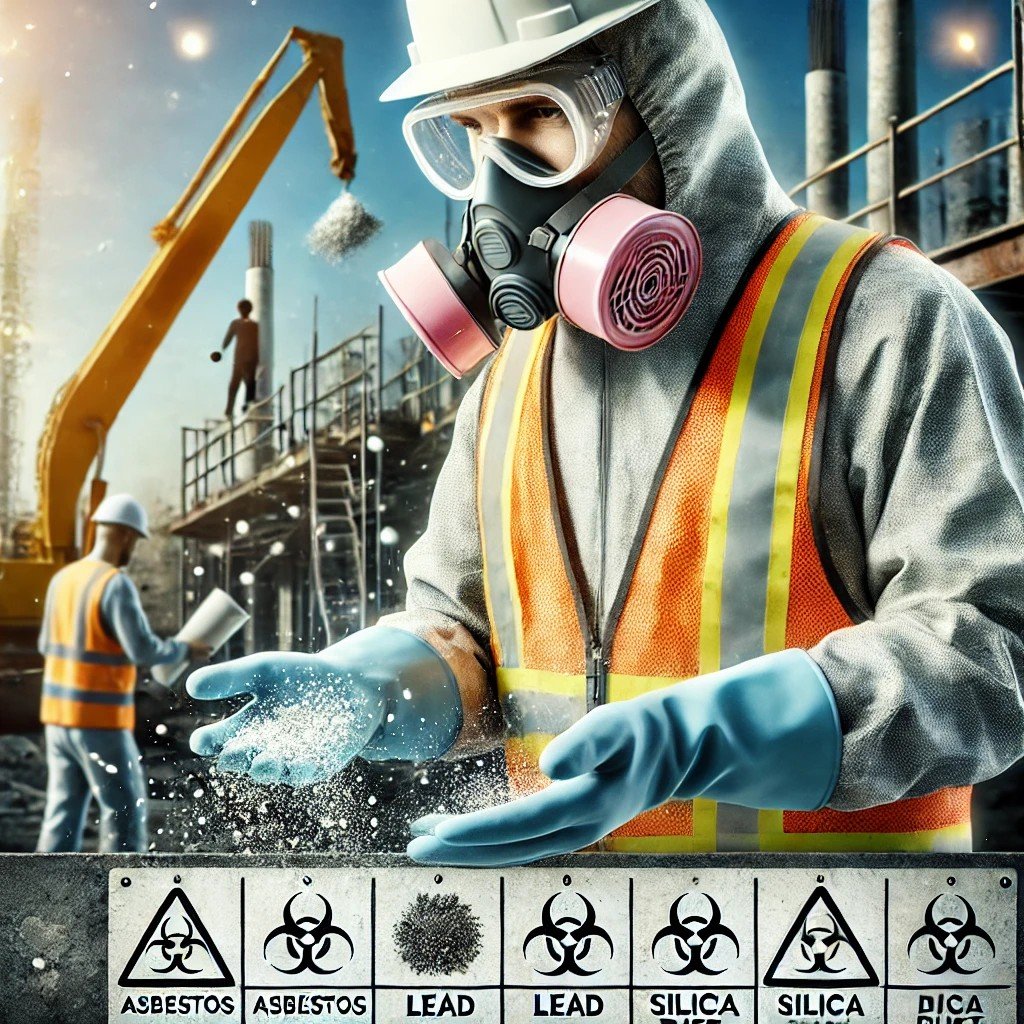

Module 7 - health hazards in construction

Health Hazards in Construction

This module focuses on recognizing and managing health hazards on construction sites. Workers are often exposed to hazardous substances, excessive noise, and environmental conditions that can lead to long-term health issues. Understanding these risks and implementing control measures can help ensure a safer work environment.

study guide

quiz osha module 7: Health Hazards in Construction

Instructions: Select the correct answer for each question.

What is the primary health risk associated with silica dust exposure?

a) Skin irritation

b) Silicosis and lung disease

c) Hearing loss

d) Eye infectionsWhich of the following is NOT a common hazardous substance found on construction sites?

a) Asbestos

b) Lead

c) Water

d) Chemical solventsAt what decibel level does OSHA require hearing protection?

a) 70 dBA

b) 85 dBA

c) 90 dBA

d) 100 dBAWhat is the most severe heat-related illness?

a) Heat rash

b) Heat cramps

c) Heat exhaustion

d) Heat strokeWhich OSHA standard regulates lead exposure in construction?

a) 29 CFR 1926.1101

b) 29 CFR 1926.62

c) 29 CFR 1926.1153

d) 29 CFR 1926.52Which control measure is considered an engineering control for dust exposure?

a) Wearing a respirator

b) Using water to suppress dust

c) Rotating workers to limit exposure

d) Conducting safety meetingsWhat is a common health effect of long-term exposure to high noise levels?

a) Increased lung capacity

b) Hearing loss

c) Improved focus

d) Reduced risk of fallsWhat type of PPE is recommended to protect against chemical exposure?

a) Hard hat

b) Earplugs

c) Gloves and protective clothing

d) Steel-toe bootsWhat should workers do to prevent heat stress?

a) Drink water regularly

b) Take breaks in shaded areas

c) Wear lightweight clothing

d) All of the aboveWhich OSHA standard regulates silica exposure in construction?

a) 29 CFR 1926.1101

b) 29 CFR 1926.62

c) 29 CFR 1926.1153

d) 29 CFR 1926.52

Module 10 - hazard communication

Hazard Communication

Hazard Communication

Hazard communication is essential in preventing workplace injuries and illnesses related to hazardous substances. OSHA's Hazard Communication Standard (HCS) ensures that employers and employees understand the dangers associated with hazardous chemicals in the workplace.

study guide

Hazard Communication Quiz

Instructions: Select the best answer for each question. Answers are at the bottom.

What is the purpose of OSHA’s Hazard Communication Standard?

a) To limit the number of hazardous chemicals in the workplace

b) To ensure employers and employees understand chemical hazards and how to protect themselves

c) To ban the use of dangerous chemicals in construction

d) To reduce paperwork related to hazardous materialsWhich of the following is NOT required on a hazardous chemical label?

a) Product identifier

b) Company stock number

c) Signal word (e.g., Danger, Warning)

d) PictogramsWhat is the primary document that provides detailed safety information about a hazardous chemical?

a) Safety Data Sheet (SDS)

b) Employee handbook

c) Manufacturer’s invoice

d) OSHA training manualWhich signal word on a chemical label indicates the highest level of hazard?

a) Caution

b) Warning

c) Danger

d) HazardousWhat should workers do if they are unsure how to handle a chemical safely?

a) Ignore it and continue working

b) Look up the Safety Data Sheet (SDS)

c) Wait until the next training session

d) Ask a co-worker for adviceWhich of the following pictograms represents a chemical that is flammable?

a) Skull and crossbones

b) Flame

c) Corrosion

d) Health hazardWhat does PPE stand for?

a) Personal Protective Equipment

b) Property Protection Element

c) Professional Personnel Equipment

d) Protective Processing EnvironmentHow often must employers provide hazard communication training?

a) Once every five years

b) Only when a worker is injured

c) Initially and whenever new chemical hazards are introduced

d) Only if OSHA requires itWhat should workers do if a hazardous chemical label is missing or unreadable?

a) Use the chemical cautiously and hope for the best

b) Immediately inform their supervisor

c) Try to guess the hazard based on smell

d) Continue working but avoid direct contactWhat is the main requirement for employers under the Hazard Communication Standard?

a) Keep safety data sheets hidden from workers

b) Provide workers with information and training on hazardous chemicals

c) Only train employees upon request

d) Ensure chemicals are used as quickly as possible to prevent storage hazards

OSHA Module 3- Electrical Safety

Electrical Hazards

Electrical hazards pose significant risks in the construction industry, leading to numerous injuries and fatalities annually. Here are some key statistics highlighting the impact of electrical hazards in this sector:

Electrocution Fatalities: Between 2011 and 2015, electrocutions accounted for approximately 8.3% of all construction-related fatalities, totaling 364 deaths.

High-Risk Exposure: Over two-thirds (70%) of these electrocution deaths were due to direct or indirect contact with electrical voltages exceeding 220 volts.

Comparative Risk: Construction workers are about four times more likely to experience electrocution than workers in all other industries combined.

Fatal Four Hazards: Electrocution is one of OSHA's "Fatal Four" hazards in construction, contributing to approximately 8% of construction worker deaths in 2021.

Nonfatal Injuries: In 2010, the construction industry had a nonfatal electric shock injury rate of 0.6 cases per 10,000 workers, higher than the private industry rate of 0.2 cases per 10,000 workers.

Overhead Power Line Incidents: Contact with overhead power lines remains a leading cause of electrocution on construction sites, with 36% of all electricity-related workplace fatalities from 2011 to 2017 attributed to such incidents.

These statistics underscore the critical need for stringent safety measures, comprehensive training, and adherence to OSHA standards to mitigate electrical hazards in the construction industry.

Lock Out/Tag Out

What is Hazardous Energy?

Energy sources including electrical, mechanical, hydraulic, pneumatic, chemical, thermal, or other sources in machines and equipment can be hazardous to workers. During the servicing and maintenance of machines and equipment, the unexpected startup or release of stored energy can result in serious injury or death to workers.

What are the harmful effects of hazardous energy?

Workers servicing or maintaining machines or equipment may be seriously injured or killed if hazardous energy is not properly controlled. Injuries resulting from the failure to control hazardous energy during maintenance activities can be serious or fatal! Injuries may include electrocution, burns, crushing, cutting, lacerating, amputating, or fracturing body parts, and others.

A steam valve is automatically turned on burning workers who are repairing a downstream connection in the piping.

A jammed conveyor system suddenly releases, crushing a worker who is trying to clear the jam.

Internal wiring on a piece of factory equipment electrically shorts, shocking worker who is repairing the equipment.

Craft workers, electricians, machine operators, and laborers are among the millions of workers who service equipment routinely and face the greatest risk of injury.

What can be done to control hazardous energy?

Proper lockout/tagout (LOTO) practices and procedures safeguard workers from hazardous energy releases. OSHA's Lockout/Tagout Fact Sheet describes the practices and procedures necessary to disable machinery or equipment to prevent hazardous energy release. The OSHA standard for The Control of Hazardous Energy (Lockout/Tagout) (29 CFR 1910.147) for general industry outlines measures for controlling different types of hazardous energy. The LOTO standard establishes the employer's responsibility to protect workers from hazardous energy. Employers are also required to train each worker to ensure that they know, understand, and are able to follow the applicable provisions of the hazardous energy control procedures.

study guide

OSHA Module 3: Electrical Safety Quiz

1. What is the most common cause of electrocution on construction sites? a) Faulty circuit breakers

b) Contact with overhead power lines

c) Poorly insulated hand tools

d) Static electricity

2. Which of the following is a key component of the lockout/tagout procedure? a) Wearing rubber gloves

b) Disconnecting power sources and using locks or tags

c) Placing warning signs on live wires

d) Using double-insulated tools

3. OSHA requires employers to ensure all electrical equipment is ___. a) Properly grounded

b) Inspected once a year

c) Connected to an extension cord

d) Stored in a dry location

4. What is the minimum clearance distance for working near overhead power lines carrying up to 50 kV? a) 5 feet

b) 10 feet

c) 15 feet

d) 20 feet

5. Which device is designed to protect workers from electrical shocks by shutting off power? a) Surge protector

b) Ground Fault Circuit Interrupter (GFCI)

c) Circuit breaker

d) Fuse

6. What is one of the primary dangers of using extension cords improperly on a job site? a) They may not reach far enough

b) They can cause electrocution or fire hazards

c) They are difficult to unplug

d) They take up too much space

7. How often should electrical tools and cords be inspected for damage? a) Once a month

b) Annually

c) Before each use

d) Only when they stop working

8. What is the primary function of grounding in electrical systems? a) To improve conductivity

b) To provide a safe path for electricity to follow in case of a fault

c) To reduce energy consumption

d) To increase voltage levels

9. Which of the following is an OSHA requirement for working in wet conditions? a) Use only battery-operated tools

b) Wear a full-body rubber suit

c) Use Ground Fault Circuit Interrupters (GFCIs)

d) Keep all electrical tools at least 5 feet away from water

10. Why is it important to follow OSHA electrical safety standards on construction sites? a) To avoid legal trouble

b) To ensure a smooth workflow

c) To reduce the risk of electrical shock, burns, and fatalities

d) To speed up construction time

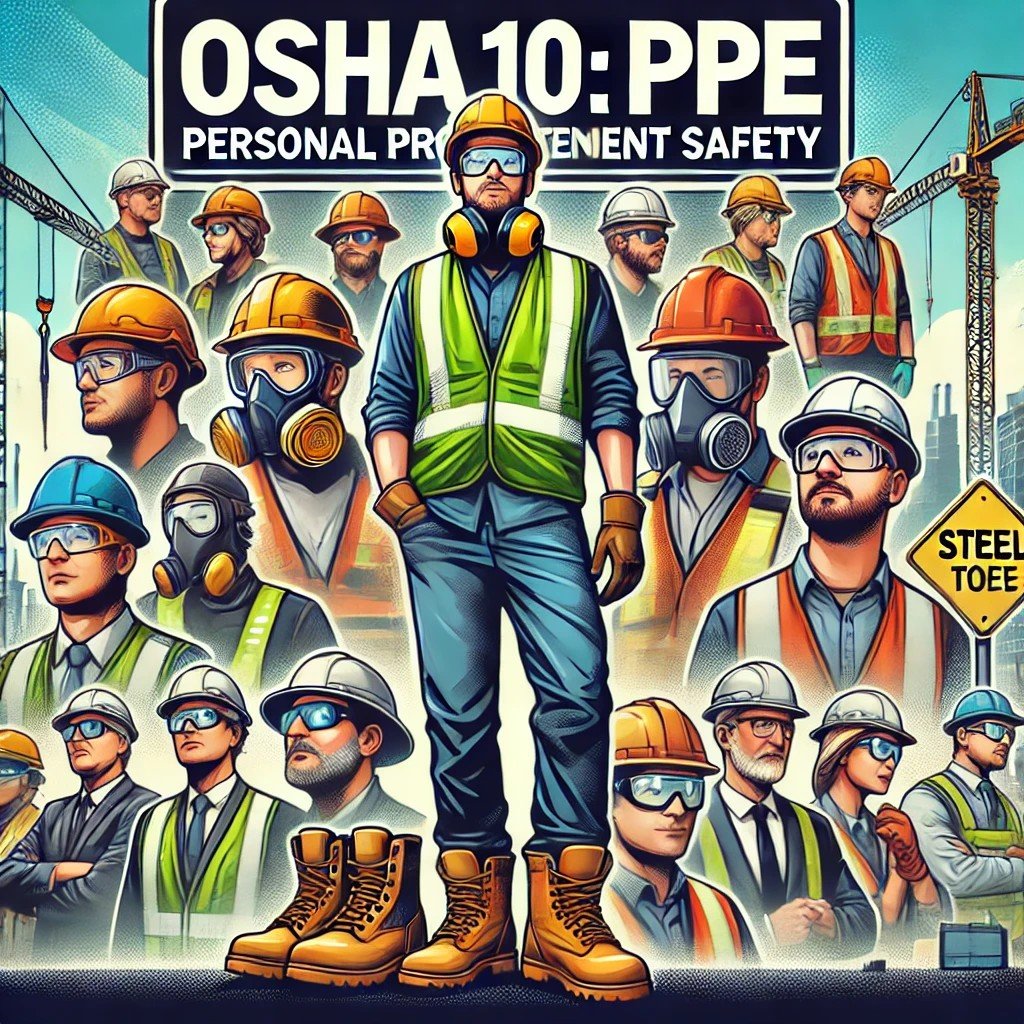

Module 5 - ppe

PPE (Personal Protective Equipment)

Personal Protective Equipment (PPE) is designed to protect workers from workplace hazards that cannot be eliminated through engineering or administrative controls. OSHA requires employers to provide PPE when necessary and ensure its proper use.

Study guide

Quiz: OSHA 10 Module 6 – Personal Protective Equipment (PPE)

1. What is the main purpose of PPE?

a) To eliminate all workplace hazards

b) To supplement other safety measures and reduce risks

c) To replace engineering and administrative controls

d) To make workers more comfortable

2. According to OSHA, who is responsible for providing PPE in the workplace?

a) The employees

b) The government

c) The employer

d) The PPE manufacturer

3. Which standard covers general PPE requirements under OSHA?

a) 29 CFR 1910.133

b) 29 CFR 1910.132

c) 29 CFR 1926.501

d) 29 CFR 1910.146

4. What type of PPE protects against falling objects and electrical hazards?

a) Safety goggles

b) Hard hats

c) Steel-toe boots

d) Earplugs

5. What type of eye protection should be used when handling hazardous chemicals?

a) Safety glasses

b) Welding helmet

c) Goggles

d) Face shield

6. Which gloves are best for handling sharp objects?

a) Latex gloves

b) Leather gloves

c) Heat-resistant gloves

d) Nitrile gloves

7. What should workers do before using PPE?

a) Inspect it for damage

b) Share it with a coworker

c) Modify it for better fit

d) Assume it is in good condition

8. Which type of footwear is recommended for workers handling electrical equipment?

a) Steel-toe boots

b) Rubber-soled, non-conductive boots

c) Open-toed sandals

d) Slip-resistant sneakers

9. How often should PPE be inspected?

a) Only when first purchased

b) Once a year

c) Before each use

d) Only when OSHA requires it

10. Why is proper PPE maintenance important?

a) To keep it looking new

b) To ensure it continues to provide protection

c) To meet employee preferences

d) To reduce the cost of buying new PPE

Module 9 - tools and equipment safety

Tools and Equipment Safety

Objective

By the end of this module, participants will:

Understand the safe use of hand and power tools.

Learn proper tool inspection and maintenance procedures.

Identify OSHA guarding requirements for tools.

Understand the safety requirements for pneumatic tools and abrasive wheels.

Study Guide

Quiz: Tools and Equipment Safety

1. What is the primary purpose of guarding on power tools?

a) To make tools look more professional

b) To increase tool efficiency

c) To protect workers from moving parts

d) To make tools easier to operate

2. Before using a power tool, what should you always do?

a) Check the weather forecast

b) Inspect the tool for damage

c) Turn it on at full power to test it

d) Lubricate all moving parts

3. What is a critical step in maintaining hand and power tools?

a) Using any extension cord available

b) Cleaning tools after use and storing them properly

c) Leaving tools on the ground for quick access

d) Spraying tools with water before use

4. When using pneumatic tools, what should be done to prevent hazards?

a) Use the highest possible air pressure

b) Ensure proper attachment of hoses and fittings

c) Avoid using protective eyewear

d) Stand directly in front of the tool while in use

5. Which of the following tools requires regular inspection for cracks and damage?

a) Hammers

b) Abrasive wheels

c) Screwdrivers

d) Tape measures

6. What is the best way to prevent electrical shock when using electric tools?

a) Wear rubber gloves only

b) Use tools with damaged cords if they still function

c) Ensure tools are properly grounded or double-insulated

d) Stand on a wet surface for better stability

7. What should you never do with a power tool?

a) Use it according to the manufacturer's instructions

b) Carry it by its cord

c) Inspect it before use

d) Store it in a dry area

8. What is a key safety requirement for using abrasive wheels?

a) Wearing long, loose clothing

b) Checking for cracks before installation

c) Holding the wheel with bare hands while running

d) Removing safety guards for better visibility

9. What is the correct way to store tools?

a) In a clean, dry place

b) In a random pile

c) In a bucket of water

d) Near a heat source for quick drying

10. Why is it important to use Personal Protective Equipment (PPE) when using power tools?

a) It slows down the job

b) It helps prevent injuries from flying debris and tool misuse

c) It is required only for beginners

d) It makes the worker look more professional